Stamped-bent parts

Freeforms created using stamping and bending technology

Freeforms

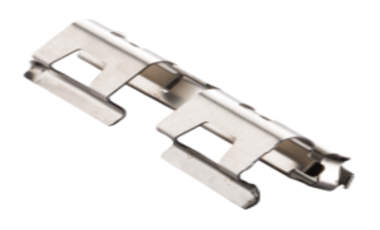

We use our stamping and bending processes to manufacture stamped-bent parts as freeforms with complex geometries, including for example clips / fasteners, pad retaining springs and furniture hinges. As your skilled development partners, our experts in stamping and bending technology support you in all project phases.

A selection of our freeforms created using stamping and bending technology:Our clips and fasteners are used for example in the automotive industry for fixing airbags or the injectors in the rail.

Dimensions- Strip thickness: 0.10 – 1.00 mm

Materials

- Hot/cold-rolled grades (also with coating)

- Carbon steels (also pre-hardened)

- Stainless steels

- Non-ferrous metals and alloys

- Special alloys (e.g. magnetic soft iron)

Design/features

- Highly complex geometries possible

- Materials with tensile strengths up to 2,000 N/mm2

- Force testing during production available

- 100% sorting supported

Downstream processes

- Deburring

- Surface protection

- Heat treatment

- Cleaning

- Testing/sorting

Take advantage of our in-depth expertise in creating freeforms using stamping and bending technology for the perfect clips for your needs.

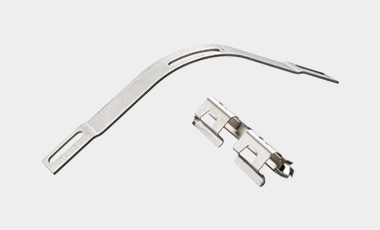

Pad retaining springs are used for fixing and damping brake pads in passenger cars and trucks.

Dimensions

- Strip thickness: 0.10 – 3.00 mm

Materials

- Hot/cold-rolled grades (also with coating)

- Carbon steels (also pre-hardened)

- Stainless steels

- Non-ferrous metals and alloys

- Special alloys (e.g. magnetic soft iron)

Design/features

- Ruberized materials also available

- Shot peening for longer service life

- Force testing during production available

Additional processes

- Deburring

- Round edging

- Surface protection

- Heat treatment

- Cleaning

- Testing/sorting

As a supplier to the furniture hinge industry, Eberle manufactures hinge components and small assemblies according to your specifications. Our machinery allows us to produce both standard forms and highly complex part geometries cost-effectively.

Dimensions

- Strip thickness: 0.10 – 3.00 mm

- Wire diameter: 0.10 – 2.00 mm

Materials

- Hot/cold-rolled grades (also with coating)

- Carbon steels (also pre-hardened)

- Stainless steels

Design/features

- Complex geometries possible

- Materials with tensile strengths up to 2,000 N/mm2

- Small assemblies and additional features such as threads, rivets and screws available

Downstream processes

- Deburring

- Surface protection

- Heat treatment

- Cleaning

- Testing/sorting

Take advantage of our in-depth expertise in creating freeforms using stamping and bending technology for the perfect furniture hinges, hinge components and assemblies for your needs.

Contact

Product group: Freeforms

Telefon: +49 (0) 8232 – 5002 – 123

Fax: +49 (0) 8232 – 5002 – 166

Mail: stanzbiegeteile@eberle-federn.de

Industry applications

Automotive

Electrical engineering

Building services engineering

Consumer goods

Mechanical engineering and equipment manufacturing

Medical technology

Other

Precision engineering